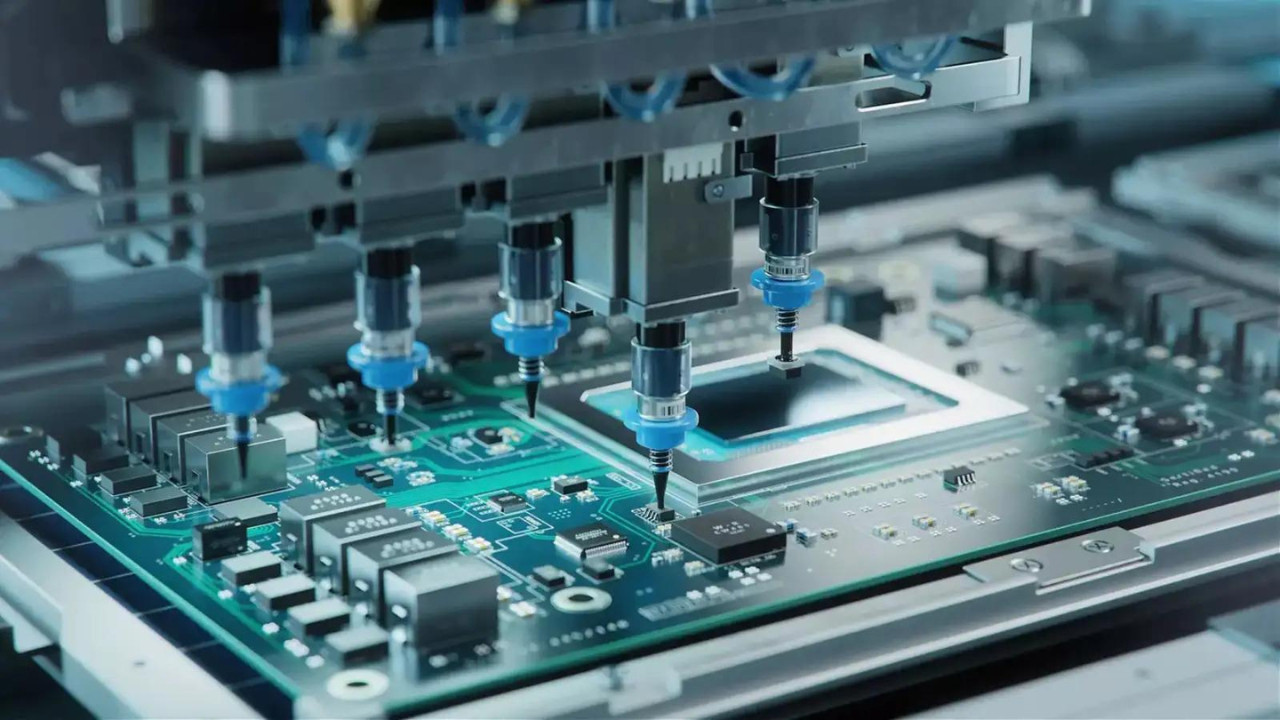

The government has greenlit 17 electronics component manufacturing projects, attracting Rs 7,172 crore in investment and aiming to create 11,800 jobs. This initiative seeks to bolster domestic companies’ role in the electronics supply chain, crucial amidst evolving global dynamics. These projects will drive production worth Rs 65,111 crore, covering vital sectors like smartphones, IT hardware, and EVs.

Riding the Semiconductor Wave: India’s Push for Electronics Manufacturing

India is making a bold play to become a global hub for electronics manufacturing, and the latest news signals a significant leap forward. Seventeen projects focusing on essential electronic components have just received the green light, injecting considerable momentum into the country’s burgeoning semiconductor ecosystem. This isn’t just about assembling gadgets; it’s about building the very foundation upon which the future of technology will be built.

The approved projects span a diverse range of critical components. These components are the unsung heroes powering everything from smartphones and electric vehicles to sophisticated medical devices and industrial machinery. With these projects, India aims to significantly reduce its reliance on imports and establish a more self-sufficient and resilient supply chain.

Why Now? The Strategic Imperative

The timing is crucial. Geopolitical tensions and supply chain disruptions have exposed vulnerabilities in the global electronics industry. Nations are realizing the strategic importance of having domestic manufacturing capabilities, particularly in the semiconductor sector. India’s proactive approach aims to capitalize on this shift, attracting investments and fostering innovation within its borders. Think of it as building a technological fortress, brick by electronic brick.

Boosting Production-Linked Incentive (PLI) Scheme

These projects fall under the revamped Production-Linked Incentive (PLI) scheme, a cornerstone of India’s strategy to incentivize domestic manufacturing. The PLI scheme offers financial incentives to companies based on their incremental sales and investments, effectively rewarding them for producing more within the country. This is a powerful tool for attracting both domestic and international players to set up shop in India, creating jobs, boosting the economy, and fostering a vibrant electronics manufacturing ecosystem. The success of the PLI scheme is contingent on not just approvals, but also ensuring smooth implementation and addressing any bottlenecks that might arise.

The Ripple Effect: Job Creation and Economic Growth

The impact of these projects will extend far beyond the electronics industry itself. The increased manufacturing activity will create a cascade of opportunities, generating jobs across various sectors, from engineering and manufacturing to logistics and support services. This will contribute significantly to economic growth and improve the livelihoods of countless individuals. The government projects that these initiatives will add thousands of jobs in the coming years. Furthermore, a strengthened domestic electronics industry will attract further investments, creating a virtuous cycle of growth and innovation.

Challenges and Opportunities

While the prospects are bright, challenges remain. Building a robust electronics manufacturing ecosystem requires more than just financial incentives. It also demands a skilled workforce, a supportive regulatory environment, and a well-developed infrastructure. India needs to continue investing in education and training programs to equip its workforce with the skills needed to thrive in the electronics industry.

Equally important is streamlining regulations and reducing bureaucratic hurdles to make it easier for companies to set up and operate in India. Investing in infrastructure, such as reliable power supply, transportation networks, and logistics facilities, is also crucial for supporting the growth of the electronics industry. However, with strategic planning, proactive policy implementation, and continued investment, India can overcome these challenges and unlock its full potential as a global electronics manufacturing hub.

Consider India’s efforts to bolster its solar panel manufacturing capabilities, a parallel push for self-reliance in another critical sector. You can read more about it here: [Internal Link to Solar Panel Manufacturing Blog Post].

Looking Ahead: A Future Powered by Indian Electronics

The approval of these 17 electronics component projects marks a significant milestone in India’s journey towards becoming a global electronics manufacturing powerhouse. The combination of strategic government policies, growing domestic demand, and a skilled workforce provides a strong foundation for continued growth and innovation. As these projects come to fruition, India will not only reduce its reliance on imports but also emerge as a key player in the global electronics supply chain, driving economic growth and creating opportunities for its citizens. The next few years will be crucial in determining whether India can truly capitalize on this momentum and establish itself as a dominant force in the world of electronics. Success depends on execution, collaboration between government and industry, and a relentless focus on innovation.

URL Slug Recommendation

india-electronics-manufacturing-push